Isn’t a demo more explicit than a long talk?

About Us

Elmass Production is a company specialized in tools and machines for the production of keyways and plines, both continuous and blind. Even special shapes are possible. We can offer you a complete solution for this, ranging from our own innovative and patented tools to the machines designed for this.

Speed & Flexibility

Our tools are designed in such a way that they can be set up quickly and flexibly.

Thanks to the innovative system, we can quickly make different types of keyways/splines.

The modular tool allows you to produce all keyways/splines and special shapes.

Experience & Innovation

Since the foundation of Elmass in 1998, the Elmass system has been further expanded with the same philosophy: « Modularity« .

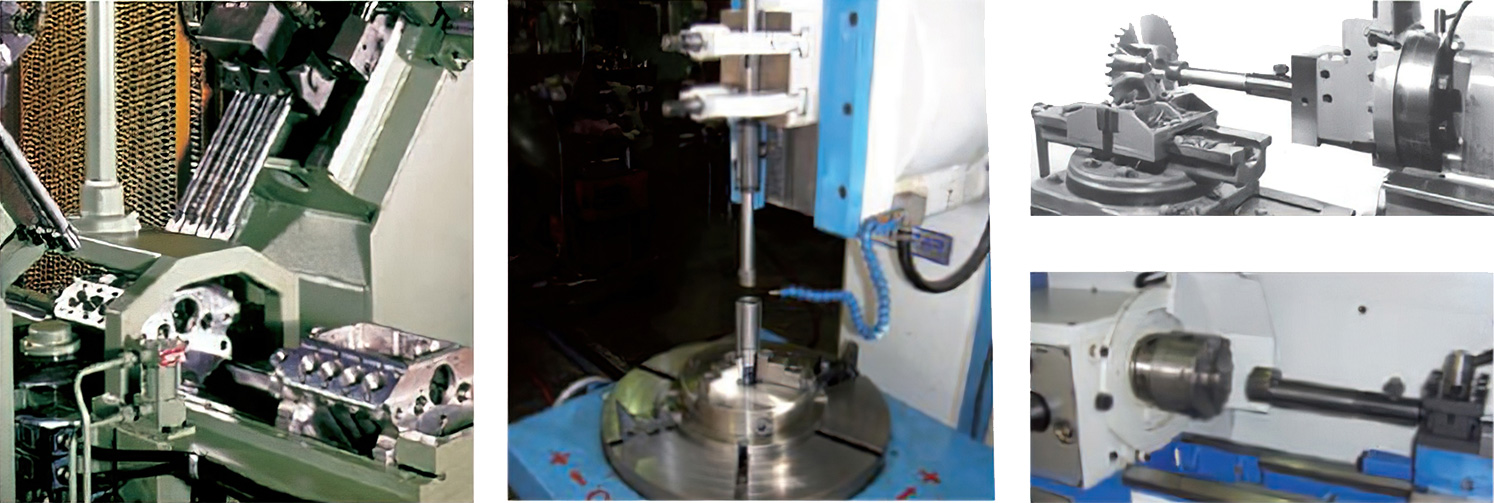

The first machines were designed at the request of the customers. In the 2000’s, we designed our first CNC machines with a user-friendly interface.

It can be equipped with various options such as turntable, hydraulic clamping, …

We have continued to innovate and design, resulting in some special machines.

- H25-4000: for producing 4000mm long internal spline

- P36-SP04: table surface of 1500x1500mm

Response & Support

Elmass is always ready to determine the right tool, set-up, machine together with you.

Thanks to our many years of experience, we can always offer you a suitable solution.

With us, the support does not stop with the purchase. You can always rely on us.

Cost Effective

The modular tool is easy to adapt allowing different types of keyways/splines to be produced with the same tool.

For example: by just adjusting the cutter, you can produce both keyways and splines with the same tool.

So you do not need any special tools for each type of splines.

The re-shapping of the cutter can be done with a regular grinder. Consequently, the operating costs are low.

Our Values

Keyways/Splines are our passion.

Customer satisfaction and service are our values.

We are ready to assist you before and after your project.

One piece production or series production, small or large parts, through-holes or blind holes, keyways/splines/special profiles, … we can offer you a solution!

Broaching System

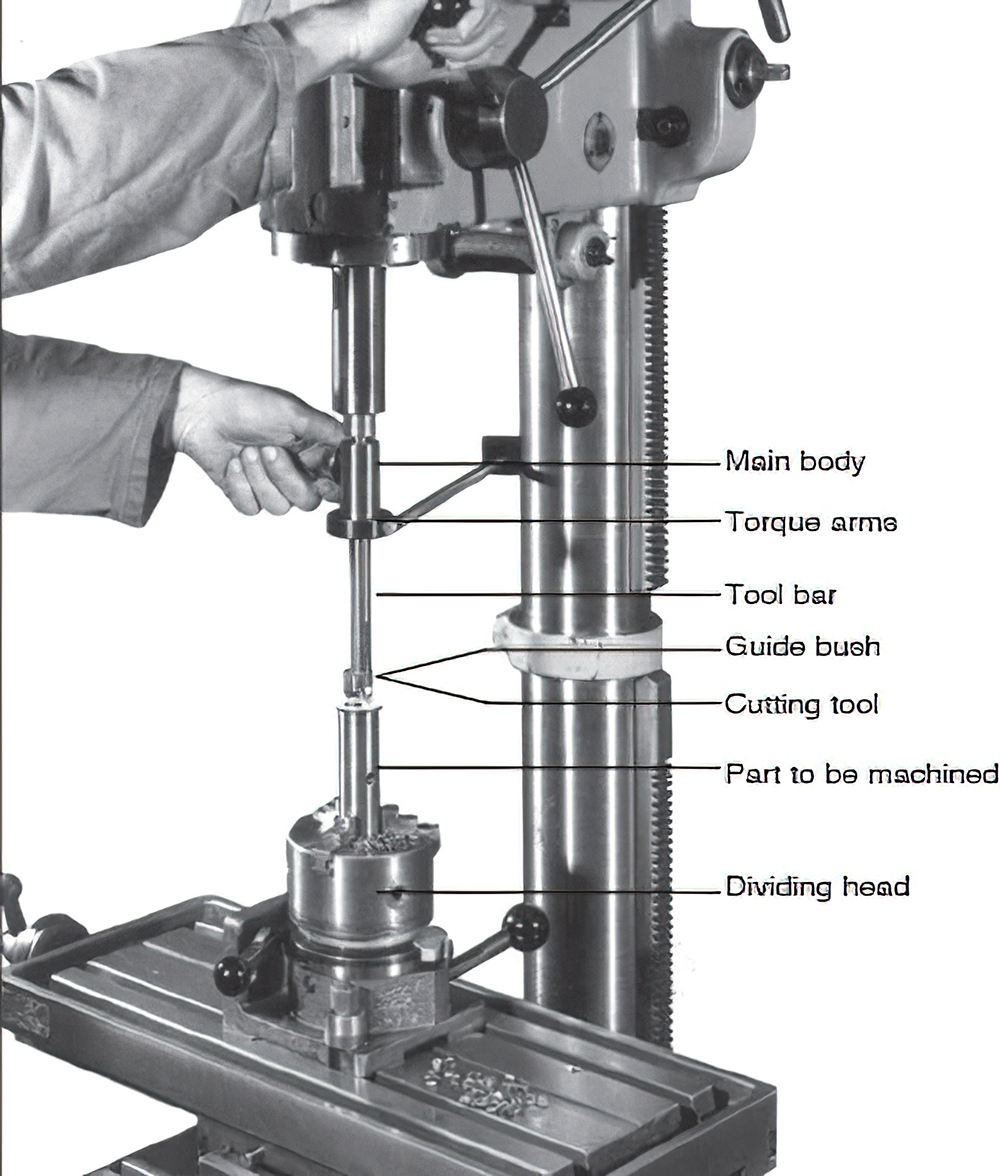

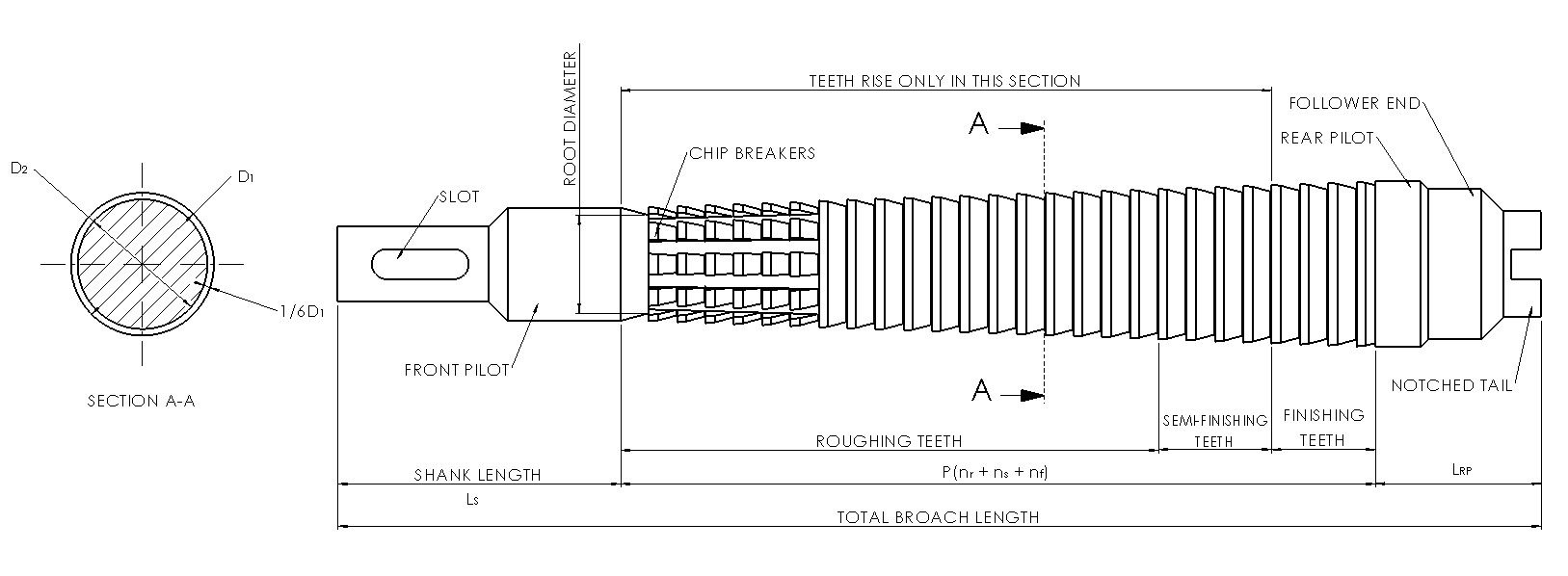

Guided broaching tools and optimized broaching machines eliminate common problems associated with conventional slotting or broaching methods. Using elmass® tools ensures a constant keyway depth over the entire bore length.

The patented elmass® technology is based on 4 key components

Guided single tooth broaching tools with a life cutting tip are designed to broach internal keyways and splines of exceptional quality in through holes and blind holes. The tools are self-centering and force the cutting tip to be at a 90 degree angle to the bore.

The eccentric guide bush inhibits any deflection of the tool bar. This results in a keyway or spline, that maintains an accurate depth over the entire length of the cut. It is ideal to broach very long keyways or splines in small bore sizes.

A range of tool bars for different applications makes the system very versatile. This includes tool bars for through bores, blind bores and mass production.

The elmass® push broaches can be used in elmass® Vertical Broaching Machines as well as in any machine that makes a linear movement (e.g. pedestal drill, lathe, slotting machine, shaper).

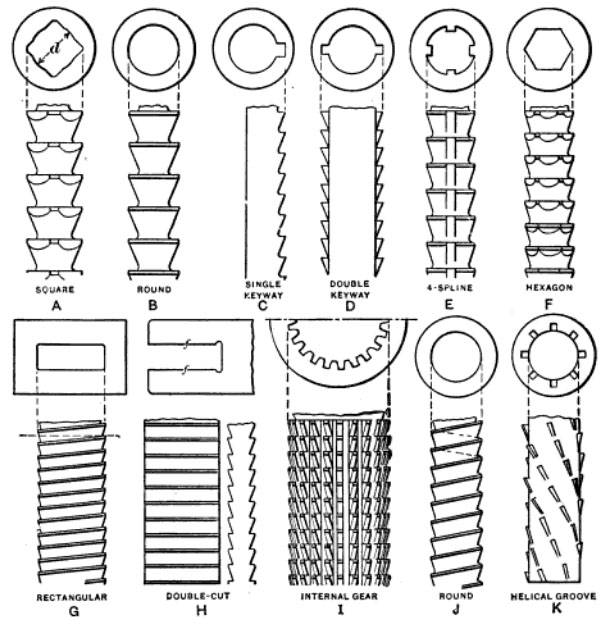

Defined cutter geometry of the single tooth cutter offers an unrestricted design of shapes. This makes the elmass® Broaching Tools ideal to cut internal keyways, involute or straight sided splines, hexagons as well as many other shapes.

The unique shape of the cutters enables them to be re-sharpened many times without losing their shape or tolerance.

Purpose formulated cutting oil lubricates the guide bush and cutter during the broaching process, protecting the cutter from overheating. It also acts as a rust inhibitor for a reasonably long time.

Vertical Broaching Machines designed to operate the elmass® push broaches in the most effective way. The NC controlled broaching machines are offered with a wide range of options. This makes them ideal for the mass production of keyways and splines and very flexible for jobbing applications.

Because the cutters are supported at the point of cutting, the cutting forces generated are unable to deflect the tool bar. Instead, the cutting forces self center the eccentric guide bush in the bore. This results in a very smooth cutting stroke without any vibration. The design of the elmass® broaching tools ensures the finished keyway has a uniform depth over the entire length of the bore

The elmass® system can be adapted to meet almost any application by matching the tool bar, guide bush and cutter. The guide bushes and cutters are interchangeable so for example, an imperial keyway can be broached in a metric bore with ease. Matching the shape of the cutter with the appropriate tool bar and guide bush allows broaching keyways, splines, hexagons and many other shapes.

The precision ground tips, which have a highly defined geometrical shape, are cut with zero clearance. We carry a large range of standard tools in H9, P9 and JS9 tolerances. Tools of any other shape or tolerance can be made to your requirements within a few days.

Use of the elmass®-system on various machines

The elmass® broaching tool simplifies slotting.

One minute is all it takes to assemble the tool. Install it on your elmass® broaching machine, pedestal drill, slotter, lathe or shaper and cut precise internal keyways, hexagons or splines in through holes and blind holes.

The cutting depth is steppless adjustable and allows the hassle-free cutting of under and over sized keyways or splines.

No shims are required! The tool is self-centring and forces slots to be in a 90° angle to the bore. The standard tolerances are H9/JS9 or P9.

The single tooth tool offers many advantages. Just by combining the desired shape of cutting tip with the appropriate tool bar and guide bush, the elmass broaching tool is convertible to cut keyways, straight sided or involute splines and hexagons.

Trusted Partners

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco.